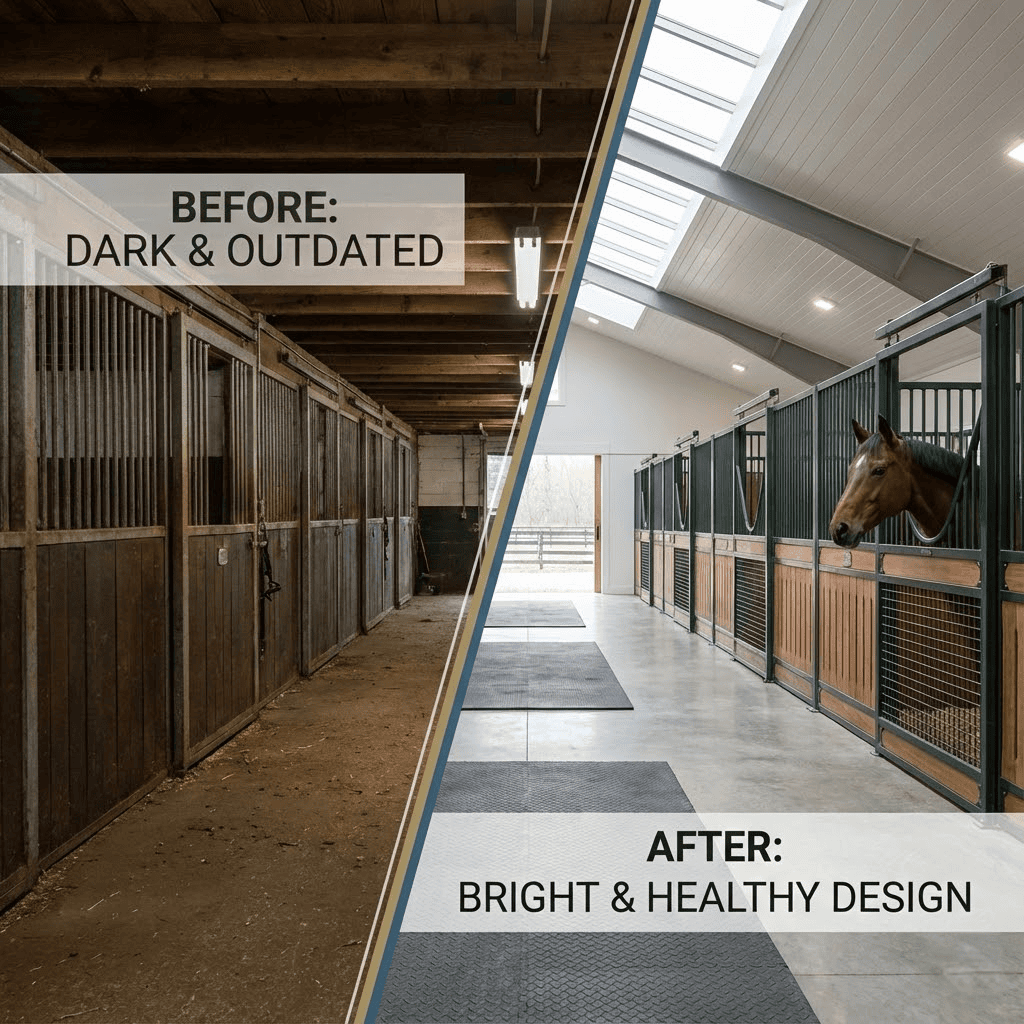

Introduction: The Paradigm Shift in Horse Stable Design

The field of horse stable design and equine facility engineering is undergoing a radical transformation in the 21st century. Constructing a stable is no longer merely a building process aimed at providing shelter to protect animals from weather elements; it has evolved into an exact science merging architecture, preventive veterinary medicine, ethology (animal behavior), and airflow physics. The modern system is an integrated bio-environment designed to simulate the horse’s natural environment as closely as possible within an enclosed space, while ensuring the highest standards of operational efficiency for human staff.

Research and field studies show that decisions made during facility planning regarding stall dimensions, flooring material selection, and ventilation systems have a direct and measurable impact on equine respiratory health, locomotor system integrity, and psychological state. Excessively hard floors are closely linked to the development of arthritis and hock sores, while poorly planned ventilation leads to the accumulation of ammonia gas and dust, exacerbating obstructive respiratory diseases. Accordingly, this report presents a comprehensive investigative analysis of optimal engineering standards, supported by technical data and economic determinants, to serve as a reference for decision-makers and engineers when constructing or renovating housing facilities.

1. Foundations of Horse Stable Design: Site Selection and Preliminary Engineering

Before delving into interior details, site selection and preparation are the cornerstones of success for any equestrian project. Advanced architectural practices indicate that neglecting land topography and natural drainage characteristics is the most costly mistake in these projects.

1.1 Site Importance in Horse Stable Design

A proper foundation needs a precise soil check. You must also assess the water table. Experts suggest a high site for natural drainage. Is the land flat or low? You must raise the building level using engineered fill. This keeps the floor above surrounding areas. Also, grade the land away from the building. Aim for a slope of 5 feet per 100 feet. This equals a 5% slope in all directions. It prevents rain from pooling near walls.

This protects the structure from dampness. It also stops mud pits from forming. Mud poses health and environmental risks. This is vital for facilities in rainy regions.

1.2 Engineering of French Drains

Surface slopes often fail in clay soil or high water tables. Engineers use French Drains here to protect foundations from rising damp. A typical system starts with a trench 12 to 18 inches wide. Workers dig this trench around the building’s perimeter. They line it with geotextile fabric. This fabric prevents fine soil from clogging the system.

Installers place a perforated pipe inside the trench. They usually choose a 4-inch diameter pipe. They position it with the holes facing downward. Then, they surround the pipe with washed gravel. The system relies on simple physics. Water follows the path of least resistance.

Water seeps through the gravel rather than saturating the soil. It enters the pipe easily. Builders must pitch this pipe at a 1% slope. Gravity then pulls the water to a safe discharge point. This keeps the sub-floor layers dry. It extends material life and reduces humidity inside the stable.

1.3 Solar Orientation and Wind

Building orientation plays a crucial role in natural ventilation and lighting efficiency. The general rule in temperate zones is to orient the building’s long axis from East to West. This allows maximum utilization of southern sunlight in winter for heating and drying, while minimizing direct exposure to harsh summer sun on long facades. In hot climates, or when relying on natural ventilation through a center aisle, prevailing wind directions must be studied. The building should be oriented so winds are perpendicular to side openings to enhance cross-ventilation, or parallel to the center aisle to act as a wind tunnel, depending on the construction strategy.

2. Spatial Standards for Stalls in Horse Stable Design

The Box Stall is the fundamental functional unit in a stable. Determining its dimensions goes beyond providing space; it relates to the horse’s biomechanics and its ability to perform natural behaviors such as lying down, rising, and turning without risk of injury.

2.1 Standard Dimensions and Impact on Horse Stable Design

Standards adopted in stall planning have evolved based on precise veterinary and behavioral observations.

Standard Riding Horses

For horses weighing approximately 1000 lbs (450 kg), the dimension of 12 × 12 feet (3.6 × 3.6 meters) is considered the gold standard and the globally recommended minimum. This area (144 sq. ft.) provides sufficient space for the horse to lie in a fully extended position (Lateral Recumbency)—essential for deep sleep stages—without legs touching the walls. This significantly reduces the risk of Casting (a dangerous situation where a horse cannot rise because it is trapped against a wall).

Large Breeds (Draft & Warmbloods)

Heavier and taller breeds, such as Warmbloods and Draft horses, require larger spaces to ensure the same level of safety and comfort. Construction standards for this category indicate dimensions must increase to 14 × 14 feet (4.2 × 4.2 meters), or a minimum of 12 × 14 feet. This increase is not a luxury but an engineering necessity to accommodate the greater axial length of these animals.

Ponies

Although small horses may adapt to tighter spaces like 10 × 10 feet, many experts advise maintaining the 10 × 12 feet standard as a minimum even for these sizes. This ensures flexibility for future use by horses of any size and facilitates airflow.

2.2 Vertical Heights

Vertical dimension is no less important than horizontal area, as it is directly linked to the volume of air available for breathing and pollutant dispersion, as well as the horse’s physical safety.

Ceiling Height

The clear ceiling height should range between 10 to 12 feet (3.0 – 3.6 meters). A height of 8 feet is the absolute minimum, acceptable only in temporary or very small structures. Low ceilings pose an imminent danger; they impede natural air circulation, increase the concentration of heat, humidity, and ammonia at the horse’s breathing level, and raise the probability of severe head injuries if the horse rears inside the stall due to panic or excess energy.

Partition Heights

Builders set the standard partition height at 8 feet. Make the lower solid portion 4 to 5 feet high. Top this solid section with a grill or bars. This design prevents horses from jumping over the wall. It also stops them from hanging their legs. A total height of 7.5 feet ensures safety. The open upper section allows better airflow. It also permits visual and social contact. This feature improves the herd’s psychological well-being. Modern engineering considers this vital for horse health.

2.3 Door and Latch Specifications in Horse Stable Design

Selecting the door type and locking mechanism is a vital part of safety engineering.

Sliding Doors

The preferred choice when planning narrow aisles and busy facilities because they do not protrude into the aisle when open, saving space and increasing safety during the movement of horses and equipment. However, the durability of upper and lower tracks must be ensured to prevent the door from derailing.

Hinged/Dutch Doors

Offer a classic look and excellent ventilation, especially if they open outward. The main drawback is their need for swing space and the danger they pose if left partially open in the aisle.

Latches

Design latches to be “Horse-proof.” A horse must never open them. However, handlers should operate them easily with one hand. Select Pin Lock or spring-loaded latches. Stainless Steel 304 offers the best durability. These options resist rust and ensure safety. Avoid latches with sharp protrusions. Sharp edges can injure the horse. This often happens during entry or exit.

3. Aisles and Workflow in Horse Stable Design

The aisle in a stable is not just a transit space; it is a central workspace, an evacuation route in emergencies, and a primary ventilation channel.

3.1 Aisle Width within Horse Stable Design Standards

Modern studies in this field indicate that the traditional aisle width (8 feet) is no longer acceptable in advanced standards due to the risks it poses.

Private Facilities

A minimum width of 12 feet is recommended. This allows two horses to pass each other with relative safety and allows a horse to turn fully within the aisle without the risk of hitting walls.

Commercial Facilities

In high-traffic areas, increasing the width to 14–16 feet is recommended. This extra space is necessary to accommodate tack trunks in front of stalls, allow the passage of small tractors and feed trucks, and provide safe areas for cross-ties without obstructing movement.

Safety and Emergency

Adequate width is a critical factor in fire or panic situations, preventing overcrowding and facilitating the maneuvering of frightened horses for a quick exit.

4. Flooring Technology in Horse Stable Design

Stable flooring is one of the most complex and expensive structural elements during project execution. It must balance a difficult equation: hardness to withstand weight and resist wear, resilience to protect horse joints and tendons, and drainage/cleanability for disease control.

4.1 Base Layers and Primary Materials

Flooring should be viewed as a multi-layered system, starting from the foundation up to the final surface.

Concrete

- Technical Analysis: The most durable and hygienic option, ideal for aisles and feed rooms. Cost ranges from $8 to $14 per sq. ft. including materials and labor.

- Biological Drawbacks: Its extreme hardness makes it unsuitable as a direct surface for stalls, causing joint stress and discouraging horses from lying down due to coldness and hardness. It is also impermeable, requiring precise slopes for drainage.

- Engineering Solution: If used in stalls, it must be fully covered with thick rubber mats or mattress systems.

Asphalt

- Technical Analysis: Offers a middle ground with costs ranging from $7 to $15 per sq. ft. It is slightly “more forgiving” on legs than concrete and has better thermal insulation properties.

- Popcorn Asphalt: Can be designed to be porous to allow vertical fluid drainage, reducing bedding needs. However, maintenance can be harder, and sanitization presents a challenge due to porosity.

Natural Floors (Clay/Sand)

- Technical Analysis: The cheapest option (less than $50 per stall in some older estimates for the top layer only), providing a comfortable, natural surface.

- Operational Drawbacks: Require very high maintenance. Horses dig holes requiring constant leveling. Most importantly, they retain urine and odors, making them a breeding ground for bacteria and a permanent source of ammonia if the top layer is not replaced regularly.

4.2 Advanced Floor Covers: Mats vs. Mattresses

This is where the real revolution in equine comfort engineering and modern construction applications lies.

Solid/Interlocking Rubber Mats

- Composition: Usually 3/4 inch thick.

- Cost: Ranges from $3 to $5 per sq. ft.

- Performance: Provide good moisture isolation and ease of cleaning. However, the main problem lies in the seams (in interlocking systems) which allow urine to seep underneath, leading to invisible ammonia accumulation. Despite being softer than concrete, they are still relatively hard and do not completely prevent hock sores.

Engineered Stall Mattress Systems

- Composition: Consists of a mattress filled with rubber crumb (up to 3 inches thick), covered by a durable, impermeable top cover secured tightly to the walls.

- Health Superiority: Veterinary studies prove that mattresses reduce pressure points by up to 73% compared to standard rubber mats. This relief significantly reduces the likelihood of hock sores and encourages horses to lie down for longer periods, improving sleep quality and recovery.

- Economic and Environmental Efficiency: Due to high resilience, mattresses do not need large amounts of bedding (shavings/straw) for comfort; they only require a small amount to absorb urine. Data indicates potential bedding reduction of up to 75%. This not only saves money but significantly reduces airborne dust, improving air quality and respiratory health.

- Cost: Initial cost is higher (can reach $8-10 per sq. ft. or more depending on the system), but ROI is achieved quickly through savings in bedding and labor.

Table 1: Brief Comparison of Flooring Technologies

| Flooring Type | Approx. Cost (per sq. ft.) | Biomechanical Comfort | Ammonia Management | Durability & Maintenance |

| Concrete | $8 – $14 | Very Poor (Harsh) | Excellent (Easy wash) | Very High |

| Clay Floor | < $1 | Good (Natural) | Poor (Retains odors) | Low (Needs constant leveling) |

| Rubber Mats | $3 – $5 | Medium | Medium (Seepage via seams) | Good |

| Mattress Systems | > $8 (Est. full system) | Excellent (73% pressure reduction) | Excellent (Impermeable surface) | High (Bedding savings) |

5. Ventilation and Environmental Control in Horse Stable Design

Ventilation is the most critical and influential element on horse health and must be given special attention when constructing enclosed barns. The engineering goal is not just “moving air,” but replacing stale air saturated with moisture, bedding dust, ammonia, and pathogens with fresh, oxygen-rich air.

5.1 Air Change Rate Standards (ACH)

Technical standards define precise air renewal rates to ensure a healthy environment, far exceeding human housing needs.

Standard Rate

Providing a minimum of 4 to 8 Air Changes Per Hour (ACH) is recommended to reduce mold spore contamination, prevent condensation on cold surfaces, and control ammonia levels. For comparison, a modern home needs only 0.5 ACH.

Required Flow Volume (CFM)

- Winter: The goal is moisture removal without excessive cooling. The recommended rate is 25-40 cubic feet per minute (CFM) per 1000 lbs of animal weight.

- Summer: The goal is heat removal. The need doubles to reach 300 CFM or more per horse to keep internal temperatures close to external ones.

5.2 Mechanics of Natural Ventilation

Effective natural ventilation relies on exploiting physical forces: Thermal Buoyancy and Wind.

Chimney Effect

Warm, moist air generated by horse bodies rises. Successful engineering of Horse Stable Design when planning must provide an outlet for this air at the highest point (Ridge Vents or Cupolas) and an inlet for fresh cool air at the lowest possible point (Inlets at eaves).

Challenges

Natural ventilation often fails due to insufficient inlet openings, creating negative pressure that prevents stale air from exiting, or because owners close all vents in winter for “warmth,” turning the place into a humid gas chamber.

5.3 Mechanical Ventilation and Ammonia Control

In harsh climates or large facilities, natural ventilation may not suffice.

Fans and Extraction

Using Exhaust Fans ensures constant air exchange rates. Studies have shown that installing mechanical ventilation systems led to a tangible decrease in carbon dioxide, ammonia, fine particles, and allergens compared to natural ventilation alone.

Chemical Ammonia Treatment

Since ammonia gas (NH3) is heavier than air and tends to accumulate near the ground (where the horse’s nose is while eating or sleeping), overhead ventilation may not be enough alone. Using ammonia-absorbing chemical additives (like Zeolite or commercial products like Sweet PDZ) on floors is recommended. Research proves that using these materials reduces ammonia concentration at ground level by up to 25%. Furthermore, using impermeable flooring (like sealed mattresses) prevents soil saturation with urine, facilitating the complete removal of the main ammonia source.

6. Lighting and Visual Standards in Horse Stable Design

Lighting in a stable is not just for visibility; it is an influential factor in equine hormonal regulation (especially estrus cycles and winter coat growth) and human work safety, making its integration into engineering plans imperative.

6.1 Recommended Lighting Levels (Lux)

Lighting must be designed to achieve specific Illuminance levels suited to the activity in each area:

Table 2: Lighting Standards in Equestrian Facilities

| Area | Lighting Level (Lux) | Functional Purpose |

| Outdoor Aisles | 25 Lux | Providing safety, security, and orientation. |

| Inside Stalls | 150 Lux | Allows precise cleaning, horse health checks, and reading medical instructions. |

| Wash/Treatment Areas | 300 Lux | High level necessary to detect small wounds, skin diseases, and ensure total cleanliness. |

| Arenas | 100 – 300 Lux | 100 Lux for routine training, 300 Lux for competitions to ensure visual accuracy and safe jumping. |

6.2 Fixture Specifications

The stable environment is classified as a “Harsh Environment” due to heavy dust, high humidity, corrosive gases, and risk of mechanical impact.

IP Rating

Lighting fixtures with a minimum rating of IP65 (dust-tight and resistant to water jets from all directions) must be used exclusively. In wash areas, raising the standard to IP66 is preferred to withstand high-pressure washing.

Mechanical Safety

All units must be equipped with shatterproof polycarbonate covers or protected by metal cages to prevent glass scattering if hit by a horse or equipment, preventing injuries and fire hazards.

LED Technology

Adopting LED technology is highly recommended for several reasons: energy efficiency, long lifespan (reducing the need to climb to ceilings for maintenance), low heat emission (reducing fire load), and immediate operation in freezing temperatures. LED also provides flicker-free lighting, which avoids disturbing sensitive horses.

7. Safety and Fire Prevention Systems in Horse Stable Design

These facilities are considered among the most dangerous buildings regarding rapid fire spread due to the massive “Fuel Load” represented by dry hay, wood bedding, and the wooden structure itself. Therefore, fire prevention must be an integral part of engineering planning.

7.1 Preventive Horse Stable Design Strategies

- Spatial Separation: The golden rule is separating the Hay Storage building from the horse housing building. Hay is the primary cause of fast-spreading fires that are difficult to control.

- Electrical Wiring: All wires must be placed inside protective conduits. Using PVC conduits is preferred in damp environments as they do not rust, and they provide protection against rodents that tend to chew wire insulation (which sometimes contains attractive plant derivatives), causing short circuits. All switches and sockets must be agricultural-grade and dust-resistant.

- Fire Extinguishers: ABC type (multi-purpose) fire extinguishers must be distributed every 50 feet (approx. 15 meters) in aisles, at every entrance, and near electrical panels.

7.2 Detection and Alarm Systems

The dusty environment makes traditional home smoke detectors useless as they give constant false alarms.

Thermal Detectors

The most suitable choice for aisles and housing areas. These devices trigger when the temperature rises above a certain limit or at a rapid rate (Rate-of-rise), making them immune to dust and humidity.

Flame and Smoke Detectors

Photoelectric smoke detectors or flame detectors can be used in clean areas like tack rooms, offices, and break rooms.

7.3 Evacuation Plans

The plan must ensure every horse has two potential “exit routes”: the front aisle door and a rear door (in ideal designs) leading directly to an outdoor paddock. All doors must open outwards and not obstruct aisles, and staff must be trained regularly on evacuation plans.

8. Operational Efficiency in Horse Stable Design

Smart planning reduces the daily distance covered by workers, thereby increasing efficiency and reducing operational costs.

8.1 Placement of Service Rooms

- Tack Room: Should be in a central location in large facilities, or near the main entrance and grooming area, to reduce effort in moving heavy equipment. This room must be well-insulated and air-conditioned to control humidity and protect leather from mold.

- Feed Room: Should be located where delivery trucks can easily access it (near an external door), but also close to stalls to facilitate distribution. It must be sealed tight against rodents.

- Wash Bays: Ideally located near the tack room (for easy cleaning after riding) and near main sewage lines to reduce plumbing costs. They must be equipped with hot and cold water, non-slip flooring (like rubber pavers or textured mats), and strong drains that prevent clogging with hair and dirt.

8.2 Manure Management

The path of manure movement from stalls to the accumulation area (Muck heap) must be planned. The collection site should be far enough to prevent odors and flies from returning to the stable, but close enough to be practical for daily use. The floor in the collection area must be solid (concrete) to prevent nitrate leaching into groundwater and designed to allow tractor access for loading and removal.

Conclusion: The Future of Sustainable Horse Stable Design

Modern engineering in horse stable design is a delicate balancing act between initial capital investment and long-term operational and health costs. Analysis shows that adhering to comfortable spatial standards (12×12 feet and up), investing in advanced flooring technologies (engineered mattresses), and applying strict ventilation systems is not merely a luxury, but a smart economic measure.

These standards directly reduce veterinary bills resulting from respiratory and joint diseases, lower labor and bedding costs, and extend the productive life of sport horses. A facility built on sound scientific and engineering foundations is a sustainable investment asset, providing a safe and healthy environment for horses and an efficient, motivating work environment for humans.